If there’s something to build, Clayton Brown is on it. A production engineer at L&M Radiator’s Hibbing, Minnesota facility, Brown displays ten years of hard work and being a team player.

Hibbing, Minnesota – The foundation of L&M Radiator’s success is teamwork. Witnesses of the company’s streamlined manufacturing process and enviable collaboration efforts might stop to wonder who is behind all the tools and resources used on a daily basis. From every cart on the floor, wash bay, and pressure test station on site, someone had to conceptualize and design this equipment to help the L&M team produce world-class radiators and coolers.

Well, one of those folks is Clayton Brown, a production engineer, who has worked with L&M Radiator for 10 years, through a period of tremendous growth for the company.

Brown started his professional career at L&M Radiator fresh out of college. In 2013, he graduated from Michigan Technological University located in northern Michigan with a desire to move back to Minnesota and put his skills and knowledge to use. After receiving a call and landing an interview at the L&M headquarters in Hibbing, Brown realized it was exactly the job he had been looking for.

As a fresh college graduate, the nerves were definitely present on his first day at the L&M Hibbing location. However, Brown quickly learned that L&M cares a lot about its employees and their success, creating an environment that inspires improvement and collaboration.

“I’ve learned a ton. At first, I didn’t know what to expect, but it’s been really cool. I’ve gotten to learn tons of different skills that I never would’ve imagined,” said Brown. “When I first started, I was tasked with designing and coming up with drawings for all the different equipment we work on, and that’s since morphed into many different roles that I’ve taken on.”

Ten years later, Brown is part of a core team department of production engineers. Together, this tight knit squad can do just about anything, from fixturing, creating templates, and testing designs to their anticipated limitations.

“We get to bounce ideas off of each other. We’re pretty open and aren’t afraid to tell each other if something is not a good idea or if it’s crazy. Our department has grown pretty tight in the last few years,” said Brown. “It just helps a lot when everyone’s on the same page and same team. It makes my day a little smoother and more enjoyable. L&M cares a lot about all the employees that work here. They are always willing to work with you.”

Finding Better Ways to Build

In the role of production engineer, flexibility is key. A typical day for Brown consists of all sorts of projects, from working on the Hibbing facility expansion project, to analyzing equipment and ensuring it is safe to use. Brown also has opportunities to travel to different L&M manufacturing operations around the world to help on those sites as well.

That’s the thing about working for L&M Radiator: everyone is on the same team. All committed to the same goal of crafting the world’s best heavy-duty equipment radiators and coolers for use in mining, oil and gas, and many other industries. L&M employees find success in working together.

There is no way to duplicate a Mesabi® radiator. L&M takes immense pride in their product and puts diligent engineering expertise to work into exceeding the needs of their customers. Being a part of this team means gaining new insight and constantly learning on the job. Before his career at L&M Radiator, Brown had never used SolidWorks – the 3D modeling software in use at L&M. He also had no prior knowledge of sheet metal work, and it was through his work at L&M that Brown was exposed to more experience in these practices.

As a production engineer, Brown and his skillset are valuable assets to the team’s success. Brown designs and implements equipment and procedures to improve production efficiencies as well as safety for his team members. He focuses on developing not only the equipment, but the processes, that produce the world’s best radiators and coolers.

“I’ve come a long way. I’ve contributed to different drafting procedures and found new ways to build things – better ways to build things,” said Brown. “Much of the equipment that the people on the floor touch or use every day I’ve either designed or helped build.”

If there’s something to build, Brown is on it. He brings the same hard work and dedication from work to his personal life. A few years ago, Brown bought a 100-year-old home and has since picked away at restoring it. First, he broke down the chimney and reran the ductwork upstairs. Then Brown took to the living and dining room by repainting the walls, putting up new trim, and tearing down a wall between the two rooms to open the space up. Recently, Brown redid the roof, gutters, and put in air conditioning throughout the house.

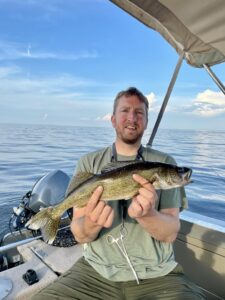

There is still much to get done, but now, Brown has a puppy named Roxy to hang out with at home. With a new teammate on deck, Brown enjoys bringing Roxy along to hunt, fish and ride four-wheelers – exposing her to all the things he loves to do.

Join The L&M Radiator Team

Interested in a career at L&M Radiator? Visit our Careers page for more information.

For more stories similar to this one, visit The Mesabi Exchange.